If you’re looking for engineered wood flooring you may have noticed that some are 15mm while others are 20mm, and within the 15mm engineered floors that there are different specs such as 2 ply 15mm, 3 ply 15mm and 3 layer 15mm engineered.

To the untrained eye, the measurements can appear a little confusing. If you’re struggling to understand engineered wooden flooring thickness, you’re not alone.

Thankfully, the experts at Ted Todd are on hand to give a detailed explanation of the right engineered flooring thickness for you. Within this guide, we’ll be exploring the different thicknesses and answering your questions. Firstly, what’s the difference between 15mm vs 20mm?

What’s The Difference Between 15mm & 20mm Engineered Wood Floors?

The 15mm and 20mm measurements refer to the overall thickness of the board. This is the primary difference between the two, and your choice will depend on how thick you want your floor to be. Most of Ted Todd’s engineered floors are made up of thin layers of wood which are bonded together with the top layer being made of hardwood. For 20mm floors this top layer is thicker, up to 6mm, while our 15mm floors have a 3.5mm or 4mm hardwood wear layer.

This is important because the subfloor that the floor will be laid onto, whether it will be used with underfloor heating and the function of the room it will be installed in, will all impact on which is the right choice for you.

Which Flooring Thickness Is Right For Me?

Choosing between 15mm and 20mm wood flooring depends on the functionality of your room and your own design tastes. A 15mm floor is ideal for rooms where height is limited, providing an airy, soft touch. 20mm floors of course benefit from the thicker cut and offer added durability and versatility.

Do I Need A Sub Floor For 15mm & 20mm Wood Floors?

20mm floors can be used as sub-floors – they are strong enough to be laid directly onto joists that are up to 400mm apart (from centre to centre). 15mm engineered floors need to be laid onto a sub-floor. Make sure you factor this into your overall costs.

Underfloor heating is another consideration. While all our engineered floors are recommended for use with underfloor heating the thickness of the board does affect heat retention. 15mm planks heat up quicker but don’t hold the heat as long as 20mm boards.

Types Of Engineered Flooring Available In 15mm And 20mm Thicknesses

The flexibility within engineered wood flooring means that they can be used in areas that are susceptible to movement caused by changes in temperature and humidity, where solid wood floors wouldn’t be suitable. This means that both 15mm and 20mm engineered wood floors can be used in kitchens, conservatories and over concrete sub floors.

Having taken all the above in consideration, you can then look at each type of engineered wood floor.

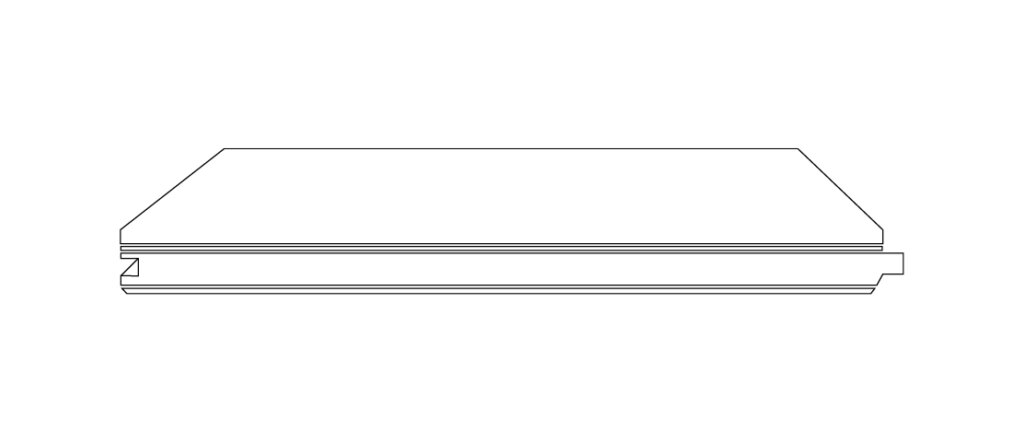

2 PLY 20MM ENGINEERED

2 ply means that each plank (or herringbone block) has two different layers of wood in the construction. Nearly all Ted Todd 20mm wood floors have a 6mm hardwood wear layer, available in different widths – the wider the width, the greater the dimensional stability. We use 100% hardwood for both layers, ensuring all 20mm boards can be used as strong structural floors. The 6mm thickness of all 20mm floors means that they can be resanded many times in years to come.

Examples: Patterns & Panels, Strada Collections

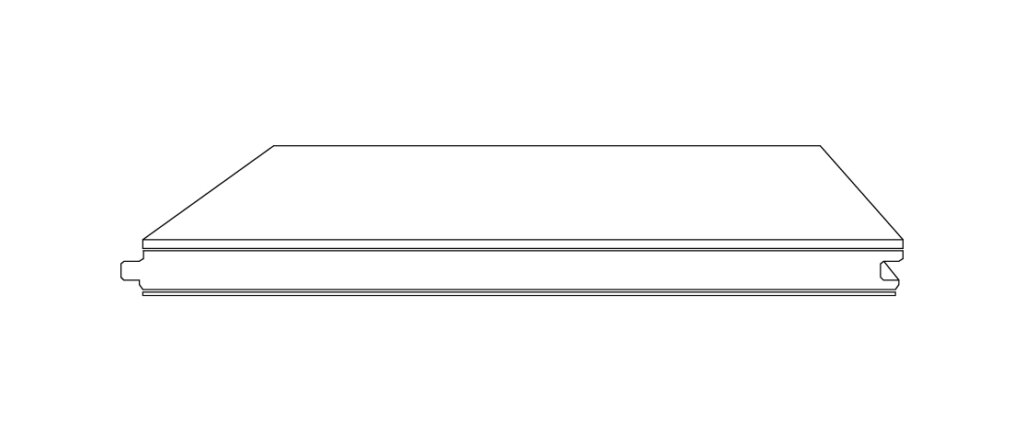

2 PLY 15MM ENGINEERED

From our 20mm 100% Hardwood engineered floor we wanted to create an engineered floor with the look and feel of a solid wood floor, but with the stability of an engineered floor. The construction of our 2 ply 15mm engineered floors is almost identical to that of the 20mm, except with a 4mm hardwood wear layer cold pressed to 11mm furniture grade birch plywood. These wood floors are consequently 50% heavier than other engineered wood floors, which aesthetically gives this floor the look and feel of a solid wood floor.

Examples: Foundation Collection

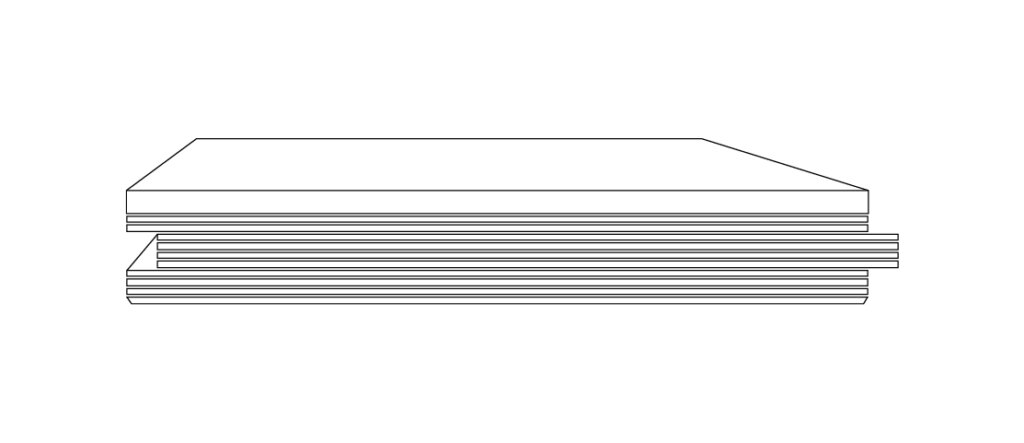

3 PLY 15MM ENGINEERED

When we designed and developed our Create Collection, we needed a bullet proof construction that would cater for not only planks and herringbone, but also small squares to ensure that there were dozens of patterns available. All of these elements needed to work together precisely and this is why we developed this 100% Oak engineered wood floor, giving advanced stability and the look and feel of a solid wood floor.

All our 3 ply 15mm engineered floors are constructed from 3 layers of solid Oak with a 4mm hardwood wear layer. The top layer is cold pressed bonded to a 7mm Oak core layer and counterbalanced with a 4mm Oak back layer for stability. It’s ideal for complex patterns where you need advanced stability.

Examples: Create Collection planks, herringbone, chevron and squares.

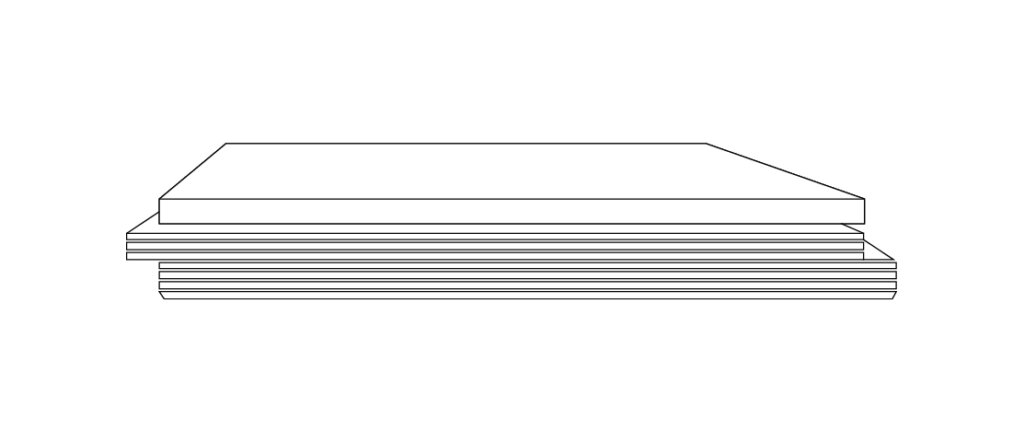

3 LAYER 15MM ENGINEERED

As wood floors became more popular we found that our customers also wanted to install Ted Todd hardwood floors in projects that required a more simple construction without sacrificing stability. Our solution was to introduce an engineered wood floor with a softwood core.

The top layer of our 3 layer 15mm engineered wood floors is a 3.5mm hardwood wear layer. This is pressed to a softwood core and softwood back layer.

Examples: Project Collection and Warehouse Collection