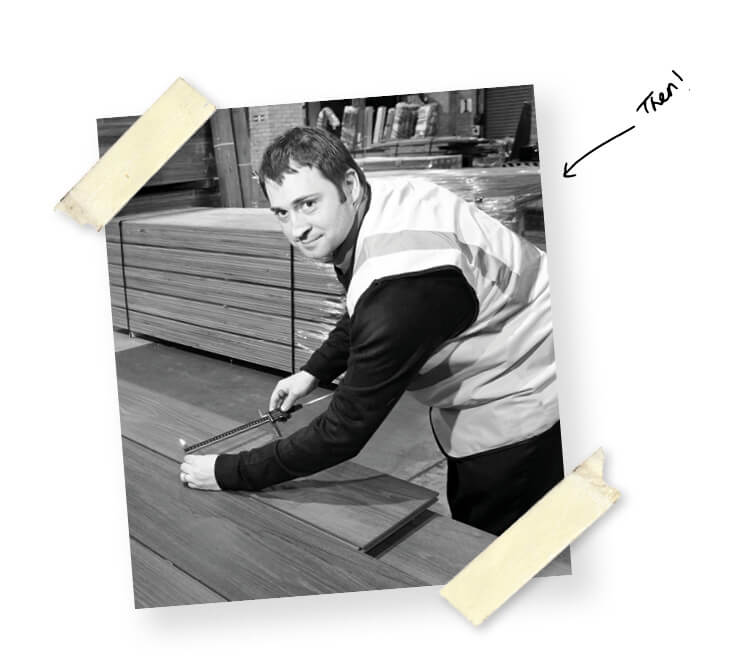

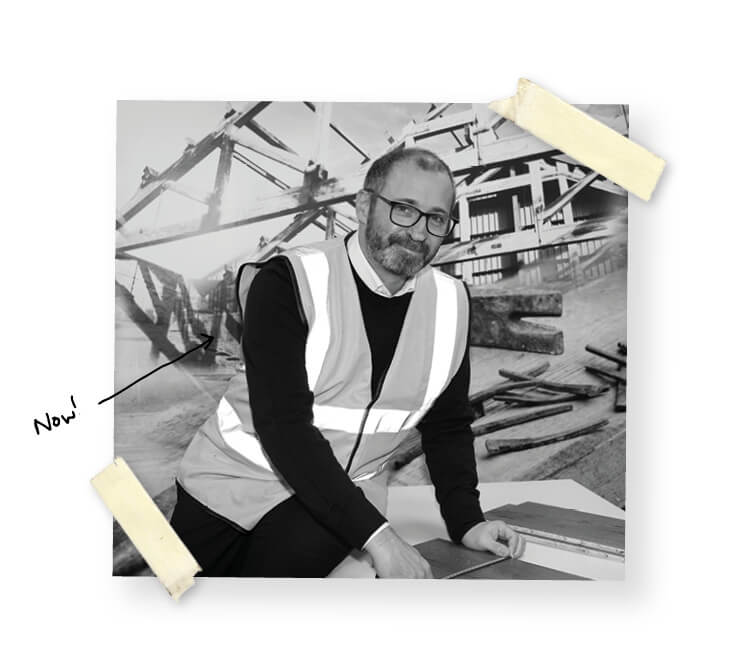

Like a wood floor that gets better with age, Jon Ashbrook, Head of Product Development, has been an integral member of the team since the beginning. We caught up with Jon to get an insight into his day, learn more about how product development shapes the floors you use in your projects and shine a light on his 27 years at Ted Todd.

How long have you worked at Ted Todd?

27 Years and 7 months – I was 19 when I started, I turned 47 just before Christmas.

How did you get into product development and buying?

It was a natural progression. Throughout my years at Ted Todd I have worked in many different roles, spending time working closely with all of our different departments. Ultimately, this wealth of experience has equipped me with the knowledge of exactly what our customers want and how they want us to work with them. Working in product development gives me the scope to shape our offering to cater to our customer’s needs – and I find that so rewarding.

You have a great reputation in the business for taking on and nurturing apprentices, why is this so important to you?

As an insight into my own background, I had few formal qualifications and wasn’t experienced coming into this job. Over the years I have learned many things and almost self-taught myself with the help of Robert Walsh (Founder, Ted Todd), who guided me to become who I am today.

This is why I feel it’s so important to give young people a chance even if they don’t have the experience or qualifications to see what they can achieve, and I think the results speak for themselves. Matt Lee is now our Woodworks Manager and Alyce Cross is now a crucial part of our Product Development Team, having both started as apprentices.

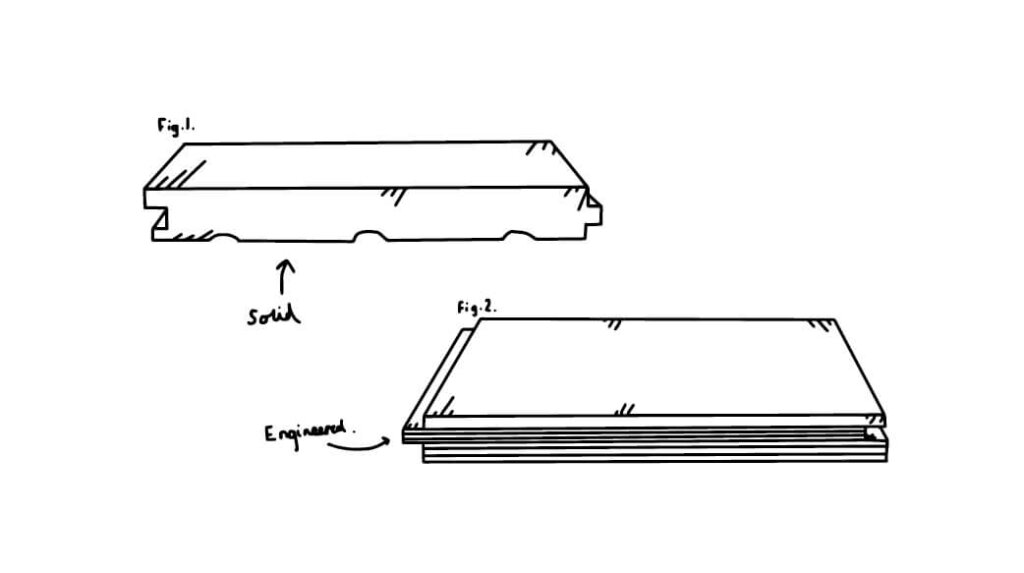

What have you found to be the biggest change in product trends over the years?

The biggest change has been the shift in demand from solid flooring to engineered flooring. This change was extremely swift in the late 2000s, and before we knew it engineered had become the dominant construction.

What do you love most about your job?

Product development is really where the magic happens!

Combining customer trends, new design ideas, modern technology and sustainability all go into developing our Ted Todd and Woodworks offering. It’s a big job – I’m calm enough to take this responsibility but also have a great team behind me.

I also enjoy sourcing the very best raw materials from all over the world.

So you get to travel the world to develop new products, what’s the best thing about these trips?

I have been to some incredible places and had some memorable journeys, but it’s extremely hard work. It’s very rewarding when new products are added to our collections, and I know that I started and developed that new floor.

What is one of your superpowers as Head of Product Development?

Definitely not invisibility, I can’t hide anywhere! I would say the ability to be calm and think the situation through. Also, longevity – I have been here so long that I must be doing something right.

How do you spend a typical day?

My typical day is like being a firefighter only less dangerous. I deal with a lot of departments and because the business moves at such a pace so there is always something that requires my attention. So, a typical day for me goes by very quickly indeed!

Tell us something that you’re particularly proud of from your time at Ted Todd?

It is incredibly rewarding to get to do my bit for the planet. One of my big responsibilities is ensuring that we are always using sustainably sourced timber and although 90% of our products are already FSC™ and PEFC certified, it’s my goal to get this to 100% in the next few years.

When Ted Todd first started sourcing new raw material in 1997, we were one of the very first companies in Europe to be FSC™-certified. We have had our certifications renewed successfully ever since! I am so proud of my team for leading the way in this area and for working for a business that truly lives their brand values.

When developing new products, sourcing the very best sustainable raw material is key. Over time, as we have come to learn more about the importance of traceability, it comes as second nature to keep the CoC (Chain of Custody) at the forefront of new product development. Today, we strive to ensure that the CoC is never broken and that all certified timber is used and not mixed.

I am so proud of my team for leading the way in this area and for working for a business that truly lives their brand values.

How do you like to unwind?

Cruising – what else?